Successfully Lower Rubbing With High-Quality Bearing Bushings

One reliable means to attain this is through the use of high-quality bearing bushings. In this discussion, we will certainly discover the importance of birthing bushings, the variables that influence rubbing in equipment, the advantages of making use of top notch bushings, and give practical ideas for selecting and installing them. Let us embark on this trip to discover just how high-quality bearing bushings can successfully minimize rubbing and enhance the efficiency of equipment.

Importance of Bearing Bushings

Birthing bushings play a critical function in guaranteeing the smooth and effective procedure of various mechanical systems. These small elements are made to lower friction and provide support for turning or gliding shafts. By serving as a buffer between moving parts, birthing bushings aid to reduce deterioration, prolong the lifespan of equipment, and boost total performance.

One of the vital features of bearing bushings is to minimize rubbing. When two relocating surfaces come right into get in touch with, friction is generated, which can create wear, power, and warm loss. Birthing bushings are made from products with low coefficients of friction, such as bronze or self-lubricating polymers, which assist to reduce this rubbing. This permits smoother and more reliable motion, reducing the stress on the machinery and improving its total energy performance.

Along with minimizing friction, birthing bushings likewise offer support and security to turning or gliding shafts. They help to maintain proper placement and protect against excessive motion or vibration, ensuring that the mechanical system operates smoothly and dependably. Without the assistance of bearing bushings, the shafts might be prone to misalignment, causing raised friction, wear, and possible damage to the whole system.

Variables Influencing Rubbing in Machinery

As the smooth procedure and longevity of equipment depend heavily on minimizing rubbing, it is crucial to comprehend the different elements that add to friction in equipment. Friction is the resistance that occurs when two surfaces enter call and slide against each various other. It can lead to energy loss, warm generation, and increased deterioration of maker parts. There are several variables that impact friction in machinery.

The initial element is surface area roughness. When the surface areas of 2 components are rough, the contact location boosts, resulting in higher friction. Polishing or oiling the surfaces can minimize rubbing by smoothing out the roughness.

The second aspect is the kind and quality of lubrication. Correct lubrication creates a thin movie between the moving surfaces, minimizing straight get in touch with and lessening friction. The thickness and temperature level of the lube additionally play a considerable duty in friction decrease.

The 3rd variable is the load or stress applied to the surface areas. Greater tons enhance the surface get in touch with area and the rubbing force. Correct lots circulation and balancing are necessary to stop extreme rubbing.

Additionally, the rate of the moving components, the material properties of the components, and the ecological conditions, such as temperature and humidity, can also influence rubbing in machinery.

Benefits of Using High-Quality Bearing Bushings

Making use of top quality bearing bushings uses countless benefits in terms of enhancing machinery performance and long life. These advantages make spending in premium bearing bushings a smart choice for services running heavy equipment.

Among the main advantages of making use of top quality bearing bushings is reduced friction. Friction is a major variable discover this that can cause damage on machinery components, resulting in reduced efficiency and enhanced upkeep costs. Premium bearing bushings are developed to decrease friction, enabling smoother operation and minimizing the danger of damages to equipment components.

In addition, premium bearing bushings add to enhanced effectiveness. By reducing rubbing, these bushings aid to maximize energy transfer within the equipment, leading to enhanced productivity and reduced power consumption. This not only enhances overall efficiency but likewise helps to decrease operational prices in the long run.

Kinds Of High-Quality Bearing Bushings

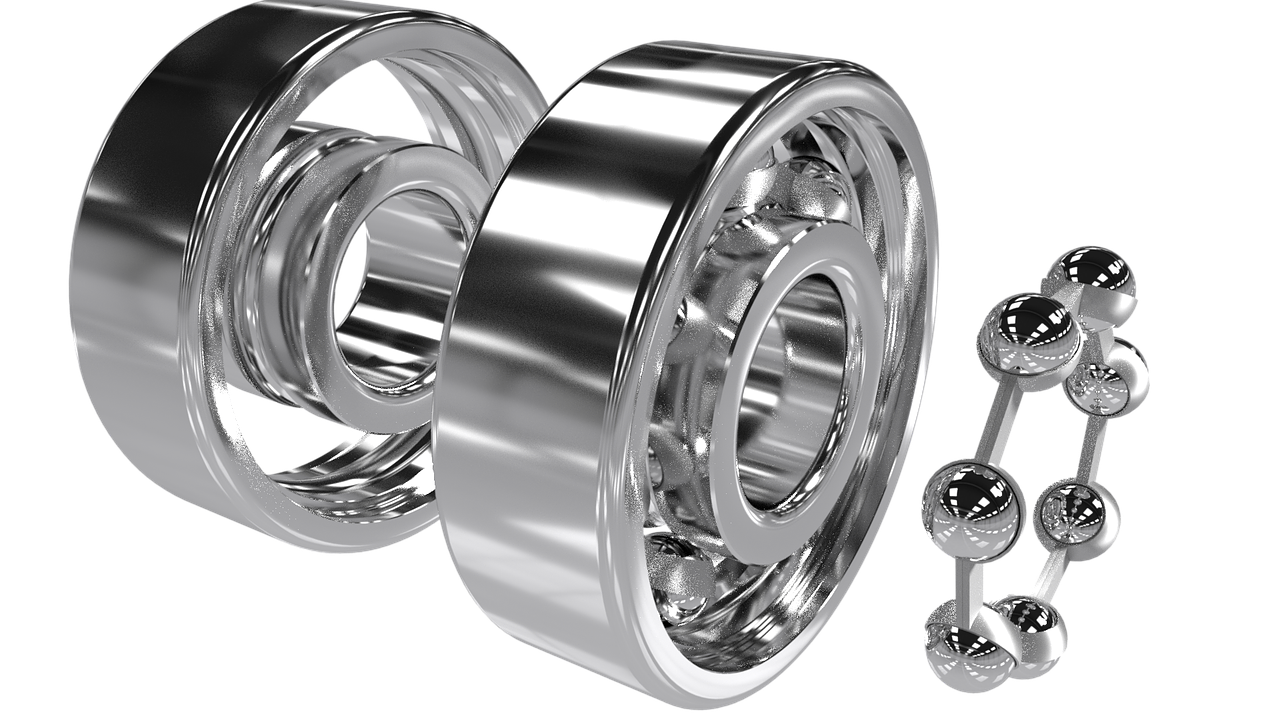

There are numerous distinct selections of premium bearing bushings offered on the market. One preferred kind is the plain bearing bushing, also understood as a sleeve bearing or journal bearing.

Another kind is the rolling element bearing bushing, which is generally made use of in applications where greater speeds and larger loads are included. This sort of bushing incorporates rolling elements such as rollers or rounds, which permit smoother and more reliable turning.

Self-lubricating bearing bushings are also widely utilized, particularly in applications where maintenance is difficult or costly. These bushings are constructed from products such as PTFE, graphite, or nylon and have built-in lubrication residential properties, eliminating the requirement for external lubrication.

Tips for Finding and Putting Up Bearing Bushings

One essential factor to consider when picking and setting up high-quality bearing bushings is to very carefully examine the details demands and applications, building on the expertise of the distinctive types mentioned in the previous subtopic. To start with, it is crucial to understand the load capability and rate demands of the application. This will help in figuring out the proper material and design of the bearing bushing to make sure optimal efficiency and longevity.

An additional variable to take into consideration is the operating atmosphere. Whether the bushings will be revealed to heats, corrosive chemicals, or extreme climate condition, it is vital to choose a product that can endure such problems without jeopardizing its efficiency.

In addition, the setup process plays a significant duty in the efficiency of the bearing bushings. It is important to make certain appropriate alignment and fitment to avoid any kind of unnecessary stress or misalignment that can result in early failure. bronze bushing. Lubrication is additionally crucial to decrease friction and use in between the bushing and the revolving shaft

Last but not least, regular evaluation and maintenance are necessary to guarantee the ongoing performance of the bearing bushings. This consists of checking for indications of wear, keeping track of lubrication levels, and dealing with any issues immediately.

Final Thought

In conclusion, top notch bearing bushings play a critical function in minimizing friction in equipment. It is essential to invest in premium bearing bushings to achieve optimum performance and long life.

In this conversation, we will certainly discover the value of bearing bushings, the factors that impact friction in equipment, the benefits of using top notch bushings, and offer useful pointers for selecting and installing them. Let us begin on this Our site journey to uncover how top quality bearing bushings can effectively decrease rubbing and boost the efficiency of equipment.

Bearing bushings are made from materials with low coefficients of friction, such as bronze or self-lubricating polymers, which aid to lessen this friction. High-grade bearing bushings are created to lessen friction, enabling for smoother operation and reducing the risk of damage to view machinery components.